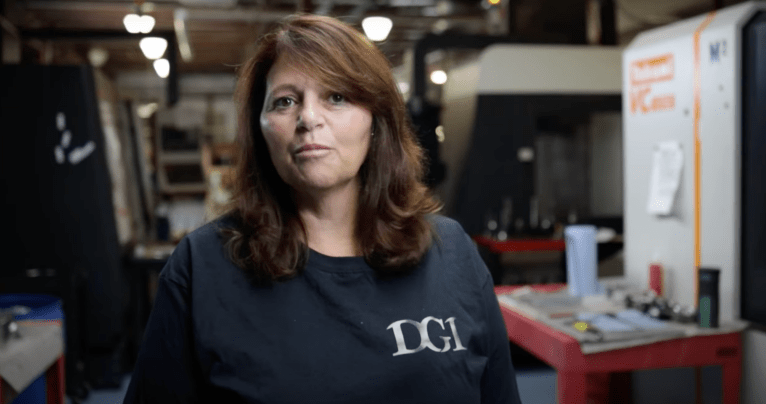

D. Gillette Industrial Services, Inc. in Easton, Pennsylvania explains how Takumi C.N.C. machines help them manufacture high-quality products for the U.S. Department …

MoldMaking Technology features the Takumi H Series double-column machining centers on page 63 of its July edition. It reads in part: “The …

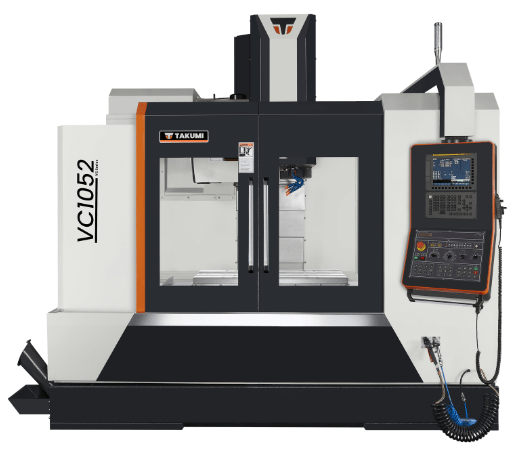

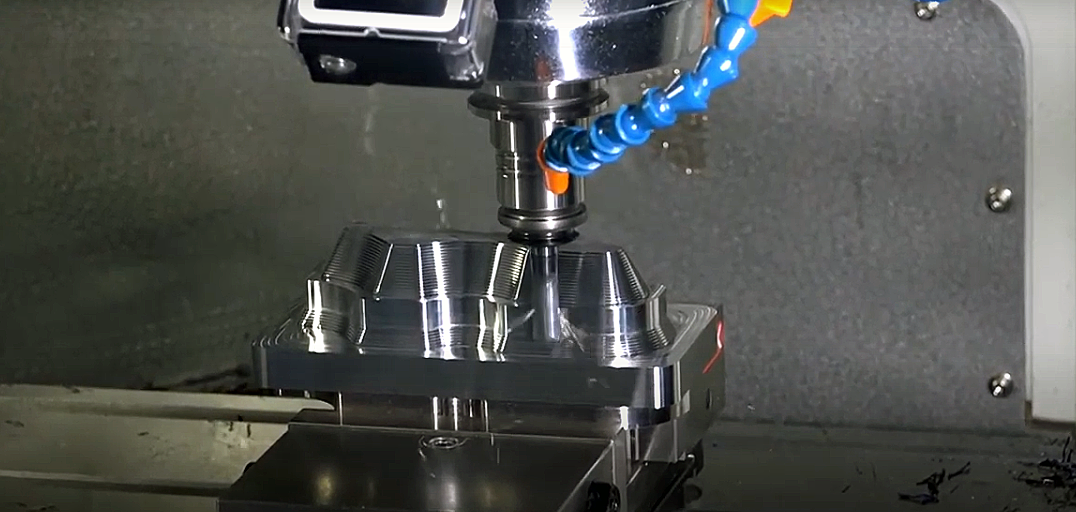

The Takumi VC1052 is a fast, three-axis linear guide machining center designed for customers focusing on batch or production work. The Takumi …

Published by Manufacturing News – December 2021 Takumi USA has adapted leading CNC controls to its durable CNC machines. We work closely …

Dennis Reinbold says he still aims to return Dreyer & Reinbold Racing to IndyCar full-time after the plan to expand its part-time presence this year was altered by the knock-on effects of the pandemic.

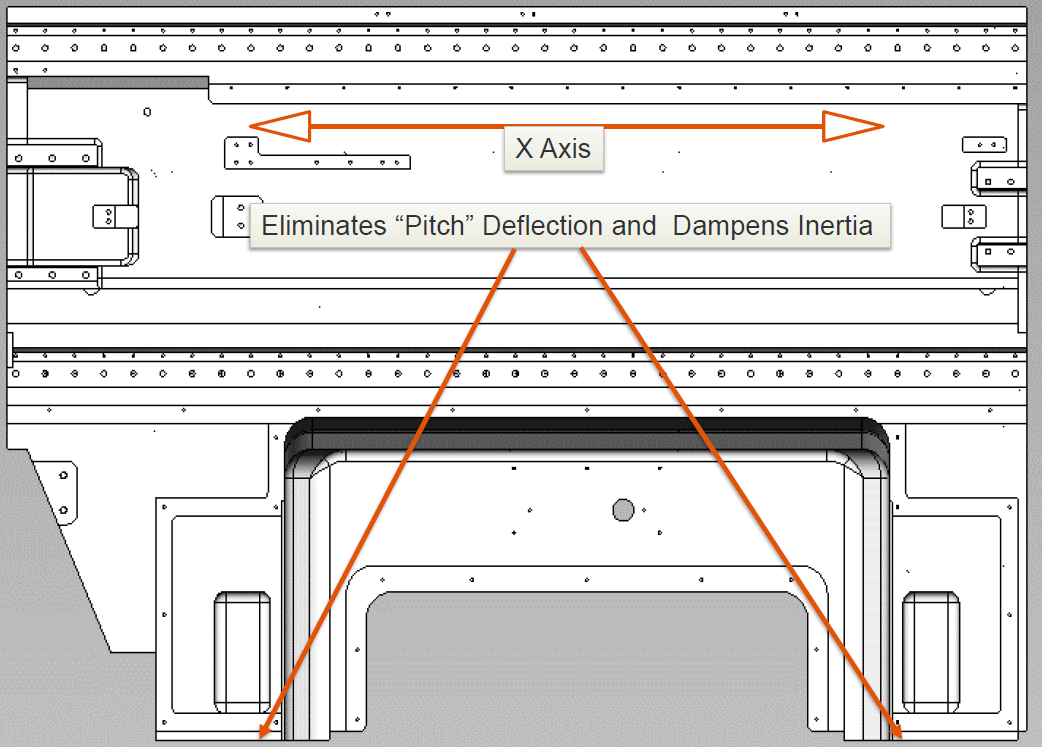

Featured in the January 2021 edition of Manufacturing News is the Takumi H10 double column machining center. The Takumi H10 is equipped with the latest FANUC 31i-MB control with 1GB data server. It has a rigid and thermally stable double-column design to support the die/mold and aerospace industries.

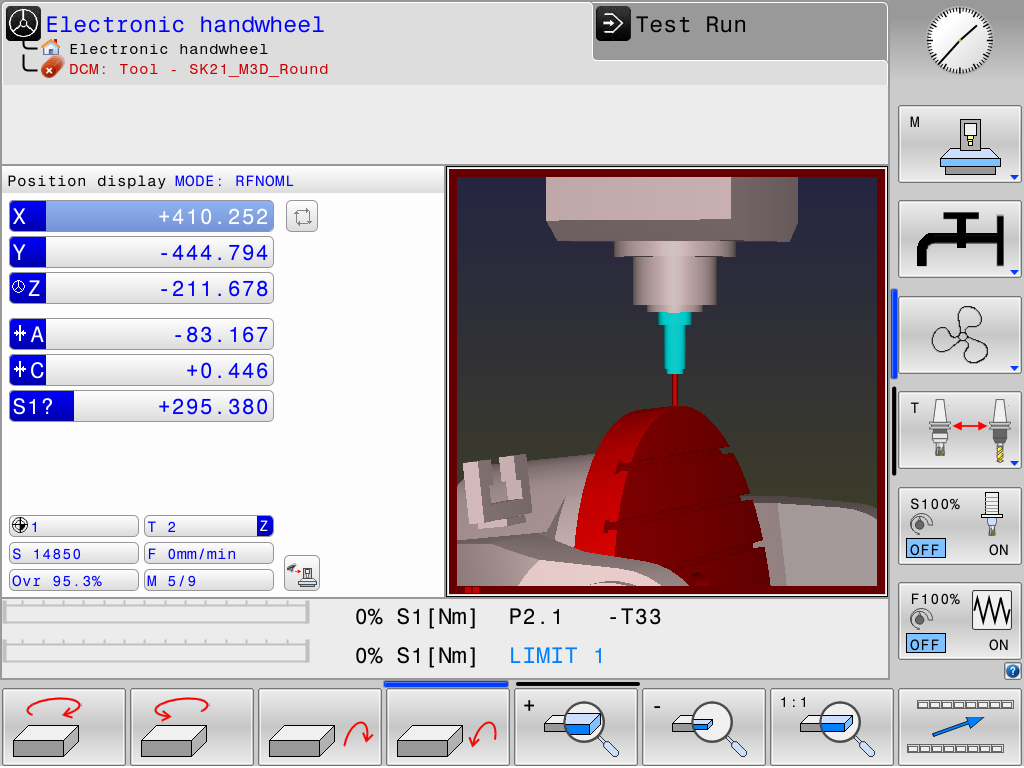

Using the Renishaw Set and Inspect App, Takumi CNC machine users can create a probing cycle, automatically generate the required machine code for the probing cycle and send it to the control.

Renishaw Set and Inspect Is the hassle associated with on-machine inspection probing finally over? Typical of many experienced machinists who have lived …

The Takumi H10 double-column machining center features a 15,000 rpm inline spindle with a Big Plus CAT 40 taper. The H Series is designed for parts requiring high speed and accuracy with good surface finish.

The U800 is a high speed gantry machining center over the high torque table that includes an 80 rpm twin torque motor on the A-axis and a 100 rpn single torque motor on the C-axis.

As 5-axis machine sales continue to increase in today’s manufacturing industry, the need for advanced control technology that assists with the adaptation …

Takumi USA sat down with one of our long-time customers Matt Miller of Instru-Med in Warsaw, IN to get his thoughts on the Takumi line of CNC machines.

Takumi USA, a manufacturer of CNC machines and a division of Hurco Companies, Inc., headquartered in Indianapolis, Ind., will have two cars in the Indianapolis 500, the largest single-day sporting event in the world, due to the company’s partnership with Indianapolis customer Dreyer and Reinbold Racing (DRR). The Takumi logo will appear on both the #24 DRR car driven by Sage Karam and the #48 DRR driven by J.R. Hildebrand.

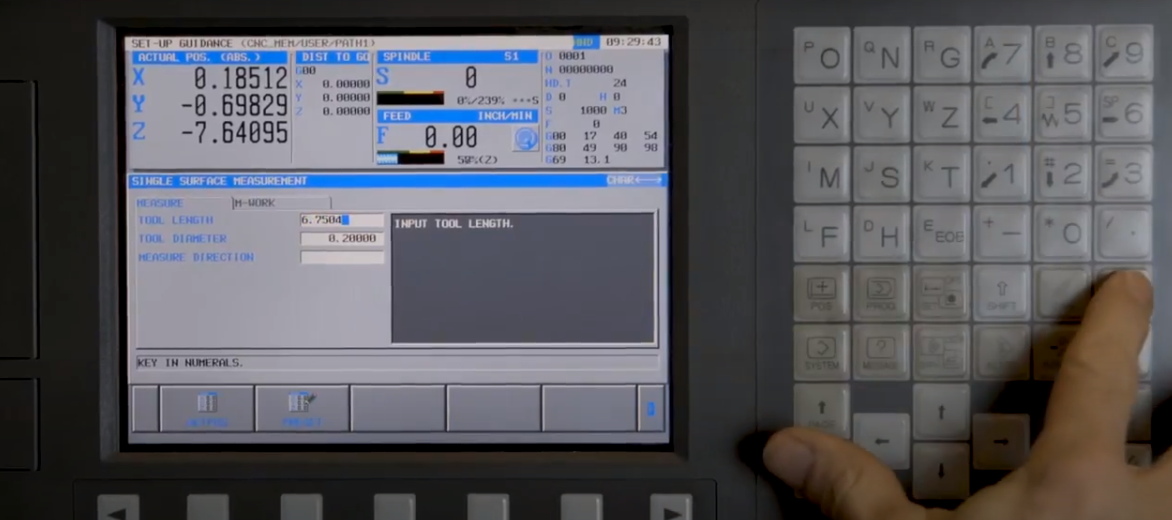

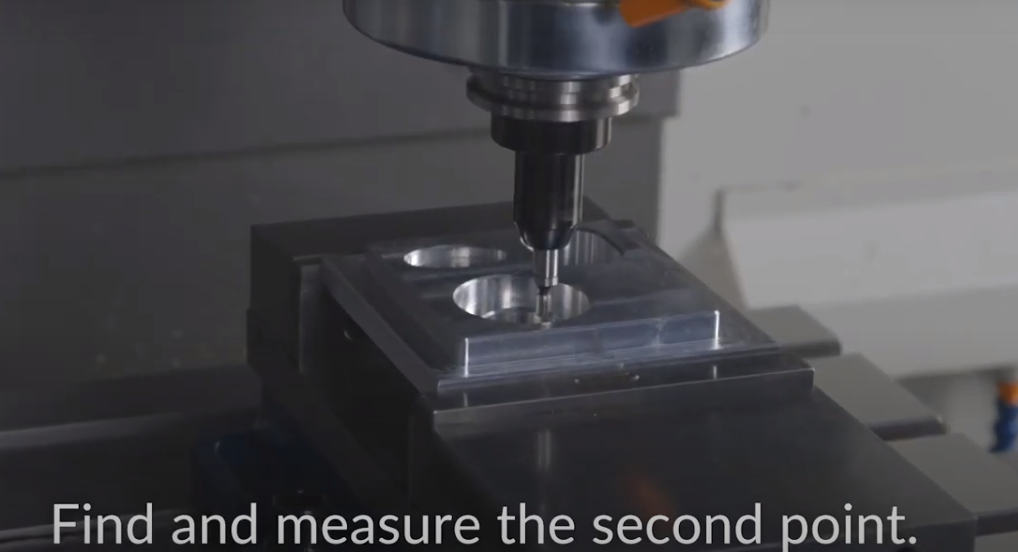

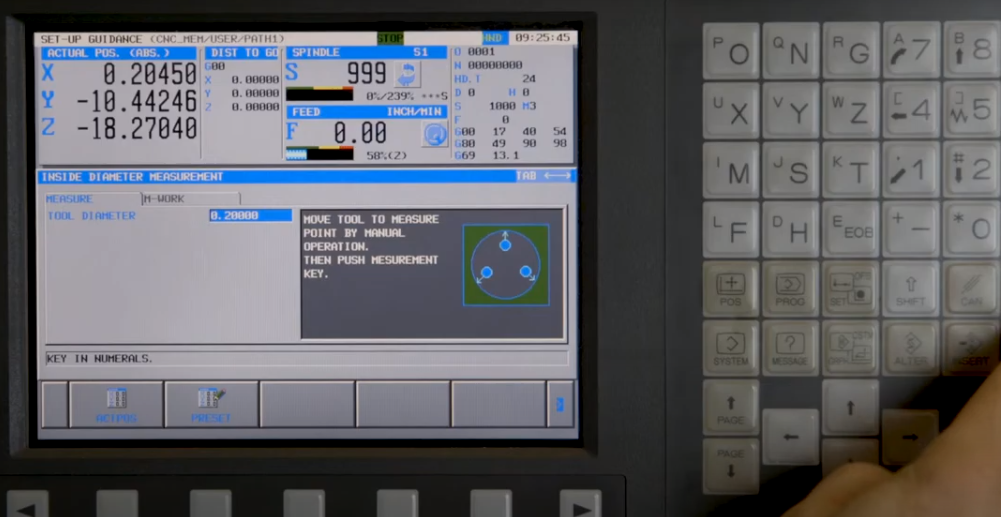

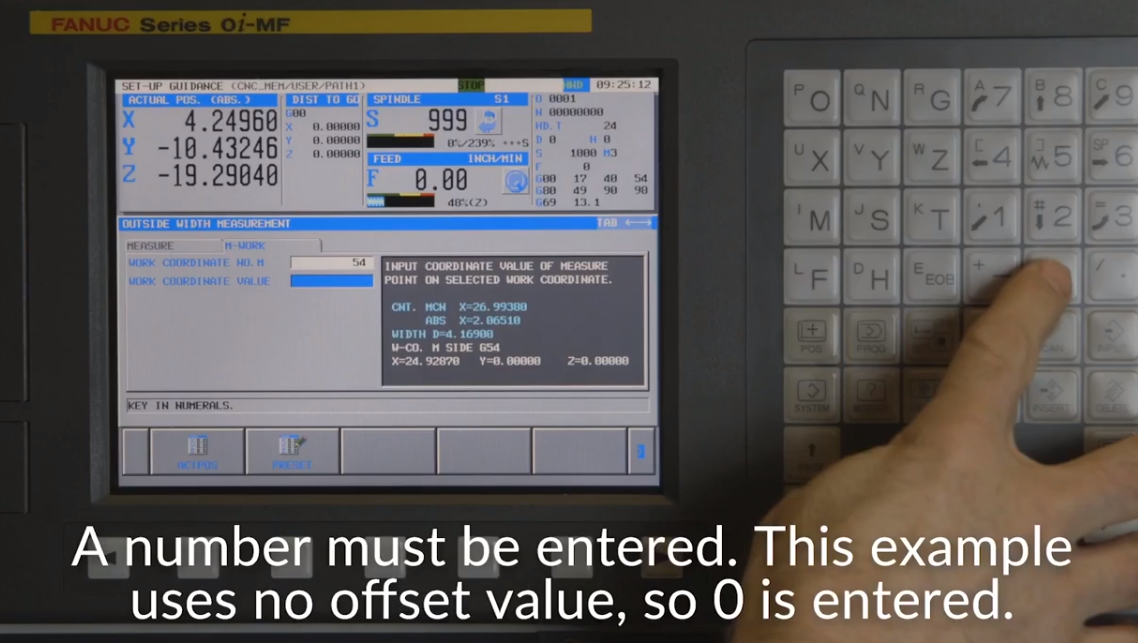

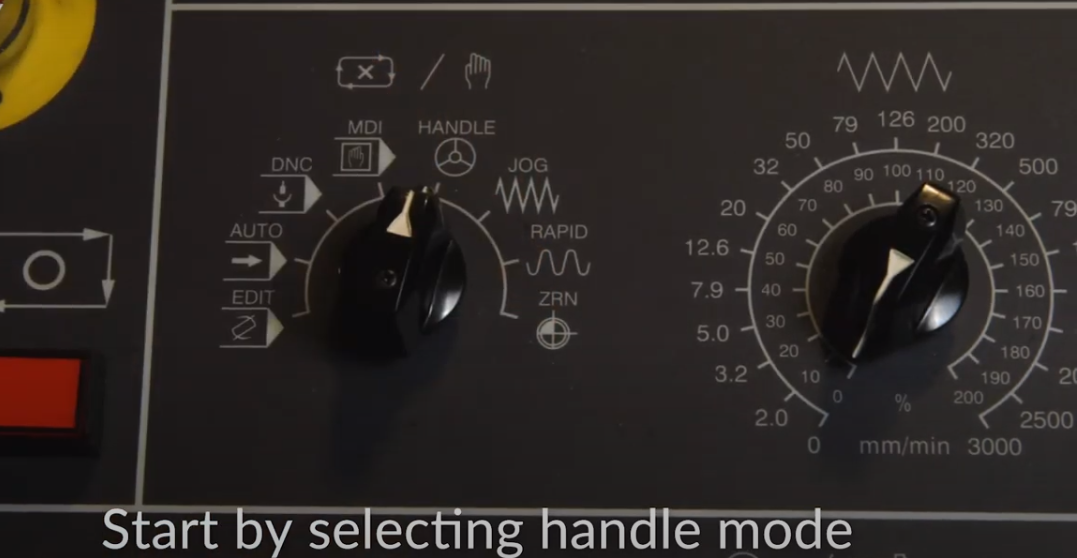

Set down your calculator and let the Takumi H Control handle the work. With the Set-up Guidance feature, you can quickly locate parts and store the calculated location to one of the included 56 work offsets with ease. Using known length tool, simply follow the prompts of the menu driven process in this video for […]

Set down your calculator and let the Takumi H Control handle the work. With the Set-up Guidance feature, you can quickly locate parts and store the calculated location to one of the included 56 work offsets with ease. Using an edge finder, simply follow the prompts of the menu driven process in this video for […]

Set down your calculator and let the Takumi H Control handle the work. With the Set-up Guidance feature, you can quickly locate parts and store the calculated location to one of the included 56 work offsets with ease. Using an edge finder, simply follow the prompts of the menu driven process in this video for […]

Set down your calculator and let the Takumi H Control handle the work. With the Set-up Guidance feature, you can quickly locate parts and store the calculated location to one of the included 56 work offsets with ease. Using an edge finder, simply follow the prompts of the menu driven process in this video and the control […]

The U800 will be featured at Takumi USA’s booth during IMTS with a 5-axis simultaneous cutting demonstration of a 20" tall replica of the famous Venus De Milo sculpture. The reproduction will be produced in 4140 steel – showcasing the rigid machine construction, speed and superior part surface finish. Programming of the Venus De Milo will be provided in partnership with Cimquest Inc using Mastercam 5-axis toolpaths.

Mark Gilmore discusses Takumi and the partnership with Cimquest.

The basic double-column design is nothing new. Searching to increase work envelopes, many companies have produced machinery with this design over the years. Large and heavy, the basic design increases the size capabilities of a CNC machine to perform large workpiece machining by spanning the table with the use of two columns and a cross […]

We recently joined our partner, Brooks Associates, to install a new machine that will mill to completion large parts for a military aircraft upgrade. As with most projects of this type, a fast install is desired, with the machine installed and options tested, ready to cut parts in the shortest time possible.

Takumi USA is proud to announce a new partnership with Capital Equipment Sales Inc. for sales distribution of the entire Takumi product line in Indiana. Capital Equipment Sales represents an array of manufacturers servicing the Medical, Aerospace, Automotive, Fluid-Power, and Electronics Manufacturing Industries. Coupled with a variety of parts, tooling, and consumables offerings as well […]

Cimquest cordially invites you to our annual Advanced Manufacturing Expo and Open House, to be held at Cimquest’s Branchburg, NJ Headquarters on October 18 & 19, 2017. As a partner of Cimquest, we have two brands of CNC machines that will be under power at this event: the Takumi H10 CNC machine equipped with the Fanuc control Representatives […]

What is Heavy Duty and Why It Matters Hi, my name is Mark Gilmore and I am responsible for technical support for the entire Takumi brand in the US and Mexico. As we grow the brand, introducing both new and updated models to the US market, I make contact with customers who purchased their Takumi […]

A2Z Manufacturing-Rocky Mountain Edition (CO, UT, ID, MT and WY) Features Takumi USA AMT Selects Takumi Mill Because It Exceeds Competitively Priced …

January 2017 Crotts & Sunders recently held a Grand Opening of its new 24,000 sq. ft. Southeast Technical Center for machine tools …

The high speed H-12 machine, designed for the die/mold and aerospace industries, is a bridge-type double column CNC machining center featuring a Fanuc 31i control.

Takumi USA is featured at Advanced Machinery, March 16th and 17th, 10am-6pm. Food and drink served all day.

Takumi USA debuts at IMTS Takumi USA made its North American debut at IMTS 2016. Sebastian Bertoncini, Takumi’s manager of operational planning, …

September 2016 – Product Preview section for IMTS High-Precision CNC Machines Three high-precision, high-performance CNC machines will be introduced to the North …

August 2016 – Takumi USA Opens Indianapolis Showroom Tech Center (Newsdesk section) Takumi USA Opens Indianapolis Showroom, Tech Center Takumi opened its …

Takumi USA would like to invite you to Machinery Sales Co. open house on November 9th from 10am to 3pm; we are looking forward to seeing you there.

Takumi USA would like to invite you to Southeast Technical Center Crotts and Saunders open house on November 15 and 16; we are looking forward to seeing you there.

A big thanks to #MastMotorsports for purchasing the first Takumi CNC machine at #Amerimold2016 at the #BraunMachinery booth. Cary Chouinard of Mast Motorsports and Tim Navalta of Braun Machinery are pictured in front of the new #Takumi V10 machining center.