Download a Quote

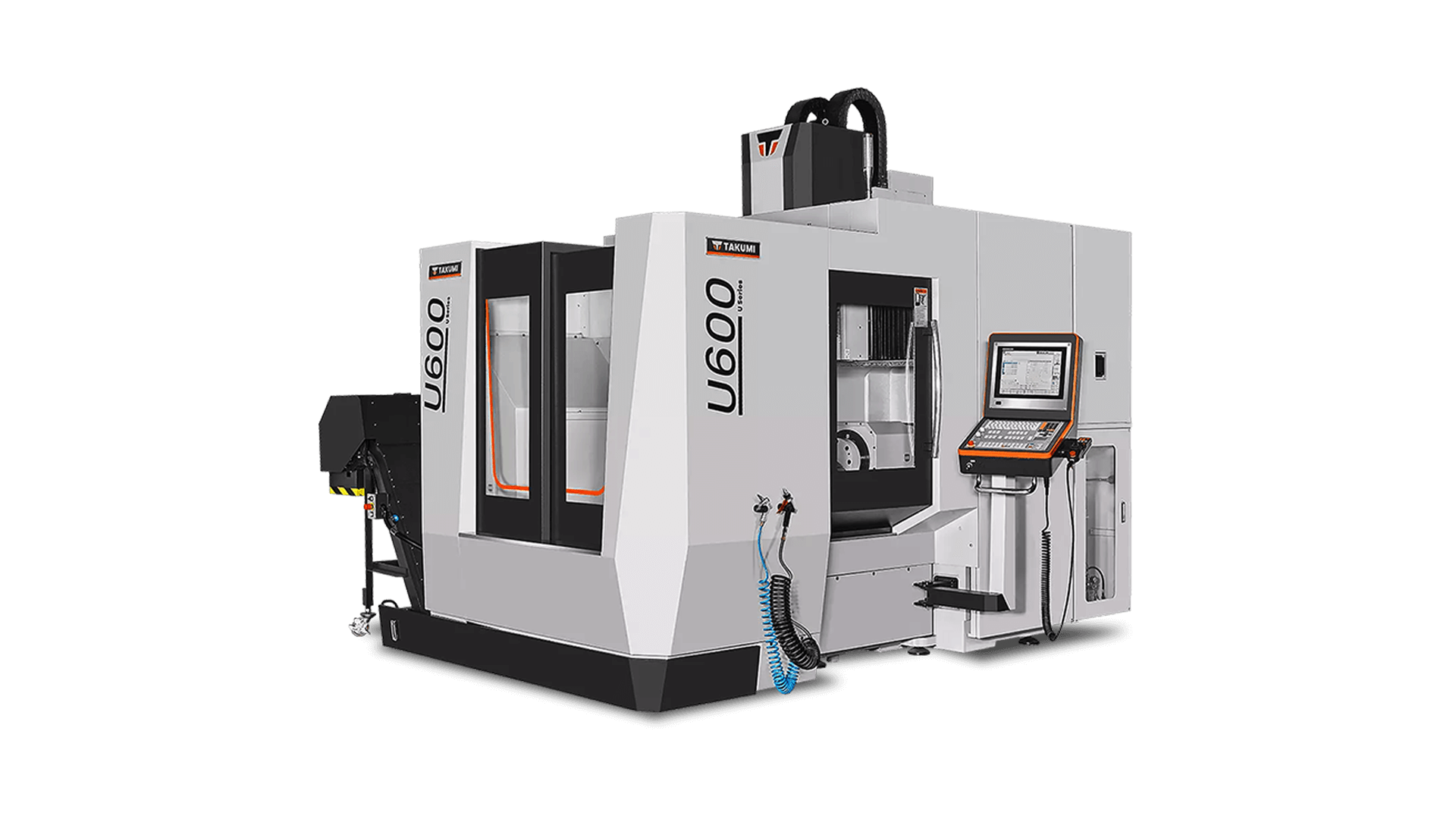

U800

5-Axis High-Speed Machining Center

The Takumi U Series 5-axis, double-column machining centers are designed for high-precision finishing of parts of all sizes, especially for die/mold, aerospace, and medical applications. The U Series has an extremely robust structure that ensures enough rigidity to perform roughing and has the speed and acceleration for finishing.

High Speed and Outstanding Surface Finish

• One-piece casting absorbs the thrust forces of high rapids and fast cutting feeds.

• One-piece, double-column design increases rigidity, enabling higher cutting feeds while maintaining superior part finish.

• Ladder design of cross rails increases rigidity and eliminates head deflection.

• Over 35 components are hand scraped for fit.

• Roller-type linear ways support faster feedrates, higher rigidity, and smoother linear motion due to larger contact area compared to ball-type linear rails.

• Large-diameter, pre-loaded and pre-tensioned ballscrews with fine pitch for accurate motion control.

• U600 has 15000-rpm, Big Plus®, CAT 40, motorized, inline spindle; U800 has built-in spindle.

• Equipped with the latest Heidenhein TNC 640 control.

Technical Specifications

| Weight | 39683.21 lbs |

|---|---|

| Dimensions | 120.28 × 165.35 × 162.2 in |

| Control Type | Heidenhein® TNC 640 |

| Travel |

|

| X-Axis | 31.49 in (799 mm) |

| Y-Axis | 45.28 in (1150 mm) |

| Z-Axis | 29.52 in (749 mm) |

| Distance from Spindle Nose to Table | 4.92~ 34.45 in (125~ 875 mm) |

| Table |

|

| Table Size | 31.49 in (800 mm) diameter |

| Table Max. Load | 2205 lbs (1000 kg) |

| T-Slot Size | .55 x 3.94 x .28 in (14 x 100 x 7 mm) |

| Spindle |

|

| Spindle Speed | 20000 rpm |

| Spindle Power | 33.3 HP (25 KW) |

| Spindle Taper | Big Plus® CAT 40 |

| Peak Spindle Torque | 99.5 ft lb (135 Nm) |

| Coolant Thru Spindle | 30 bar / 435 psi |

| Feed Rate |

|

| Rapid Traverse (X/Y/Z) | 1890 x 1890 x 1890 ipm (48 x 48 x 48 m/min) |

| Cutting Feed Rate | 945 ipm (24 m/min) |

| ATC |

|

| ATC Type | Carousel |

| Magazine Capacity | 64 Tools |

| Max. Tool Diameter | 3.54 / 4.92 in (90 / 125 mm) |

| Max. Tool Length | 11.81 in (300 mm) |

| Max. Tool Weight | 15.43 lbs (7 kg) |

| Tool Shank | HSK-63A |

| Space & System Requirements |

|

| Machine Net Weight | 39683.21 lbs (18000 kg) |

| Electrical Power Consumption | 80 KVA |

| Pneumatic Pressure | 85.34 psi (6 kgf/cm²) |

| Operating Dimensions | 165.35 x 120.28 x 162.20 in (4200 x 3055 x 4120 mm) |

Information may change without notice. Optimum machine performance is reliant upon installation conditions at the facility, such as power supply, air supply, and ambient air conditions.