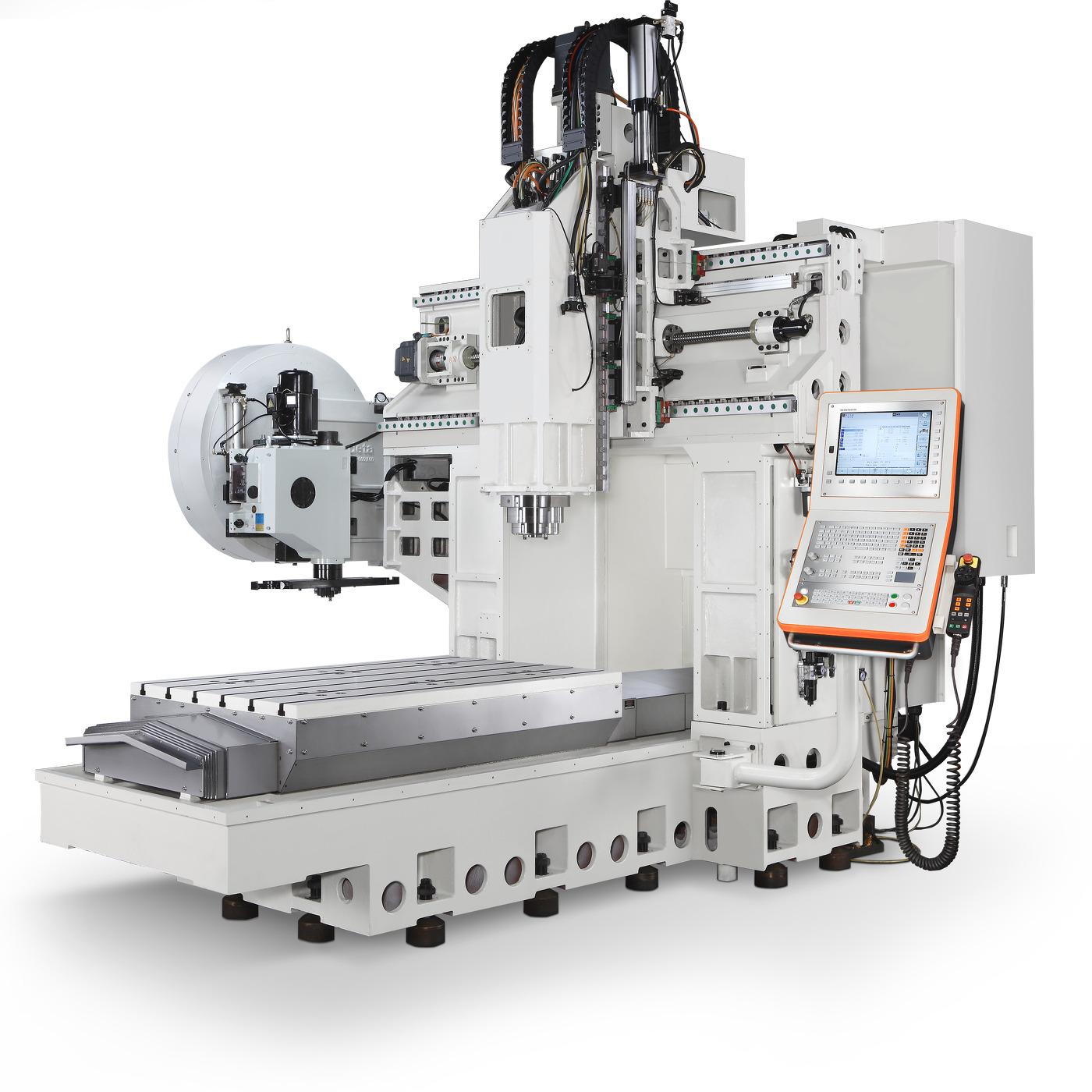

H12E

Machine Information

Product Overview

3-Axis High-Efficiency Double-Column Machining Center

H SERIES CNC MACHINES

DIE/MOLD & AEROSPACE INDUSTRIES

The Takumi H Series machining centers are designed to be dynamic and accurate as demonstrated in both surface finish, quality, and consistent precision.

Unrivaled Performance + Accuracy

• Designed for parts that require outstanding speed and accuracy, and unparalleled surface finish.

• H-Series machines offer an extremely rigid and thermally stable double-column design.

• These 3-axis models feature high-speed, inline spindles with up to 15000 rpm.

• World-class performance for die/mold, aerospace, and other high-speed applications.

• Close proximity of spindle to bridge casting reduces overhang.

• Ladder design of bridge provides greater support for the head casting.

• Swiveling control panel optimizes floor space utilization.

• Extra wide door openings facilitate convenient loading and unloading.

• Large windows provide optimal visibility.

• Robust, precision-machined castings.

• Hand-scraped contact areas.

• Linear scales ensure repeatability and accuracy.

• Roller-type rails on all axes add rigidity.

• Integrated washdown and chip management system.

• Direct-coupled ballscrews increase accuracy.

• Absolute encoders ensure fast startup.

• BIG-PLUS® spindles increase rigidity and reduce tool deflection.

• Fanuc© 0i-MF Plus Control.

Technical Specifications

| Weight | 28600 lbs |

|---|---|

| Dimensions | 203.72 × 197.44 × 137.91 in |

| Travel |

|

| X-Axis | 49.2 in (1250 mm) |

| Y-Axis | 37.4 in (950 mm) |

| Z-Axis | 22.8 in (580 mm) |

| Distance from Spindle Nose to Table | 7.87 ~ 30.7 in (200 ~ 780 mm) |

| Table |

|

| Table Size | 53.5 x 37.8 in (1360 x 960 mm) |

| Table Max. Load | 4400 lbs. (2000 kg) |

| T-Slot Size | 6 x .9 on 6.3 in (6 x 22 on 160 mm) Centers |

| Spindle |

|

| Spindle Speed | 15000 rpm |

| Spindle Power | 25 HP (18.5 KW) |

| Spindle Taper | Big Plus® CAT 40 |

| Peak Spindle Torque | 105.5 ft/lb (143.04 Nm) |

| Spindle Type | Direct Drive |

| Coolant Thru Spindle | 30 bar / 435 psi |

| Feed Rate |

|

| Rapid Traverse (X/Y/Z) | 1181 x 1181 x 1181 ipm (30 x 30 x 30 m/min) |

| Cutting Feed Rate | 0.04 ~ 787 ipm (1~ 20,000 mm/min) |

| ATC |

|

| ATC Type | Swing Arm |

| Magazine Capacity | 30 Tools |

| Max. Tool Diameter | 2.95 / 5.85 in (75 / 148 mm) |

| Max. Tool Length | 11.81 in (300 mm) |

| Max. Tool Weight | 15.4 lbs (7 kg) |

| Tool Shank | CAT 40 (BT 40 Optional) |

| Space & System Requirements |

|

| Machine Net Weight | 21627 lbs. (9810 kg) |

| Electrical Power Consumption | 60 KVA |

| Pneumatic Pressure | 5 CFM @ 85-115 psi (0.14m3 /min. @ 6-8 bar) |

| Operating Dimensions | 157.48 x 157.48 x 125.98 in (4000 x 4000 x 3200 mm) |

Information may change without notice. Optimum machine performance is reliant upon installation conditions at the facility, such as power supply, air supply, and ambient air conditions.

Standard Features & Options

Standard Features

- Roller-type linear guides on all three axes

- 15,000 rpm, CAT40, Big Plus®, inline spindle

- Hand-scraped contact areas

- Fast 1,181 IPM rapid traverse rates

- 787 IPM milling feed rate

- 30-station ATC – random access

- Oil skimmer

- Work light

- 3-light indicator lamp

- Coolant thru spindle, 435 PSI, 8.45 GPM

- Linear scales on all axes

- Lift-up chip conveyor

- Spindle thermal chiller

- Dual interior chip augers

- Manual guide

- Coolant washdown system

- Programmable cutting air-blow

- Washdown gun and air gun

- Fanuc 0i-MF Plus control with two-years parts and labor warranty

- AICC II w/400-block lookahead

- 2-MB memory

- Compact flash port/USB port/ethernet port

- Two-years parts, one-year labor warranty

- Leveling bolts and pads

- Operator Manuals

Optional Accessories

- Oil mist-cutting device

- BT tool holder conversion

- Cutting air-thru spindle

- 4th axis preparation

- Mist collectors

- Renishaw part probes

- Renishaw tool setting probes