Download a Quote

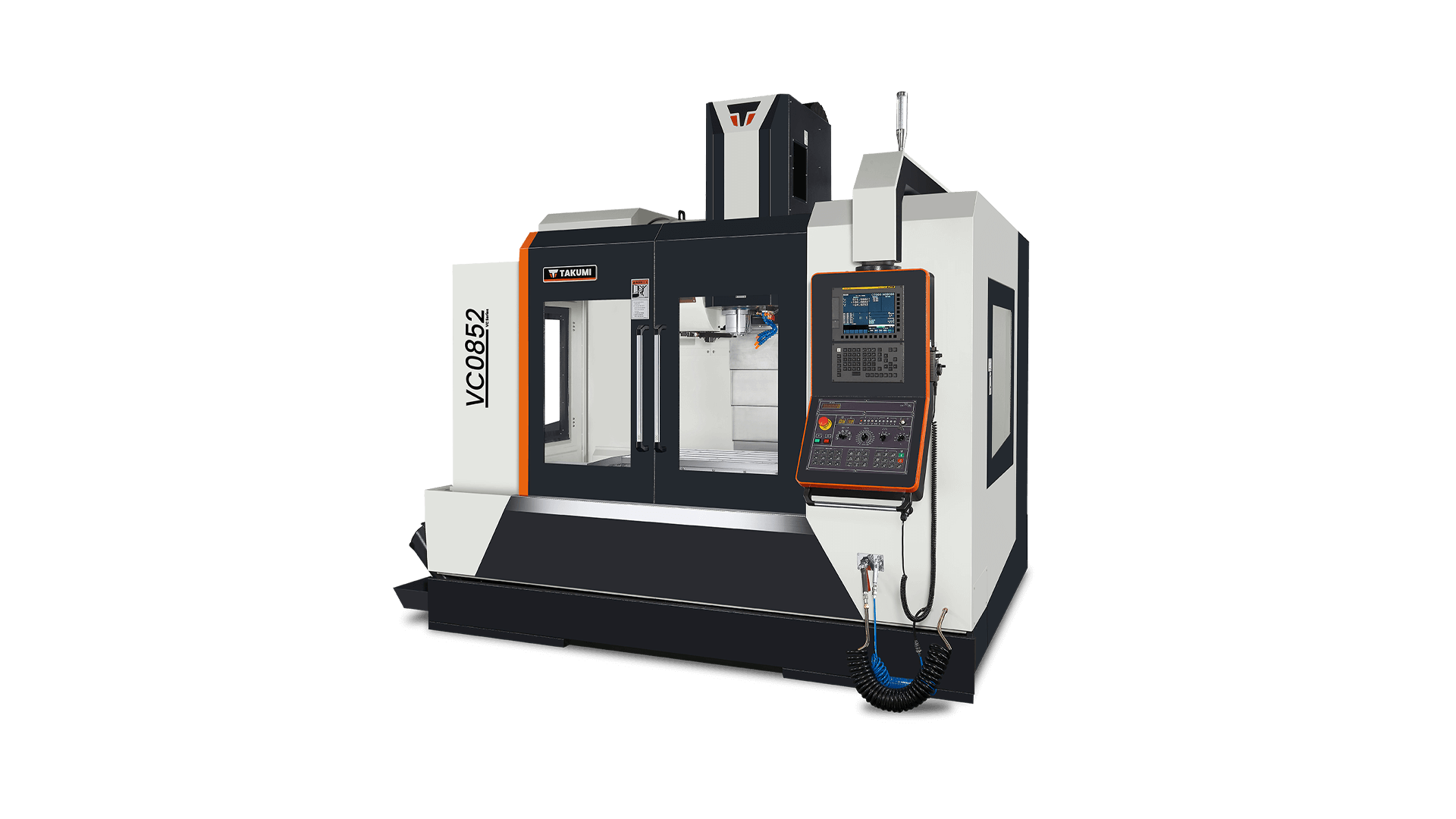

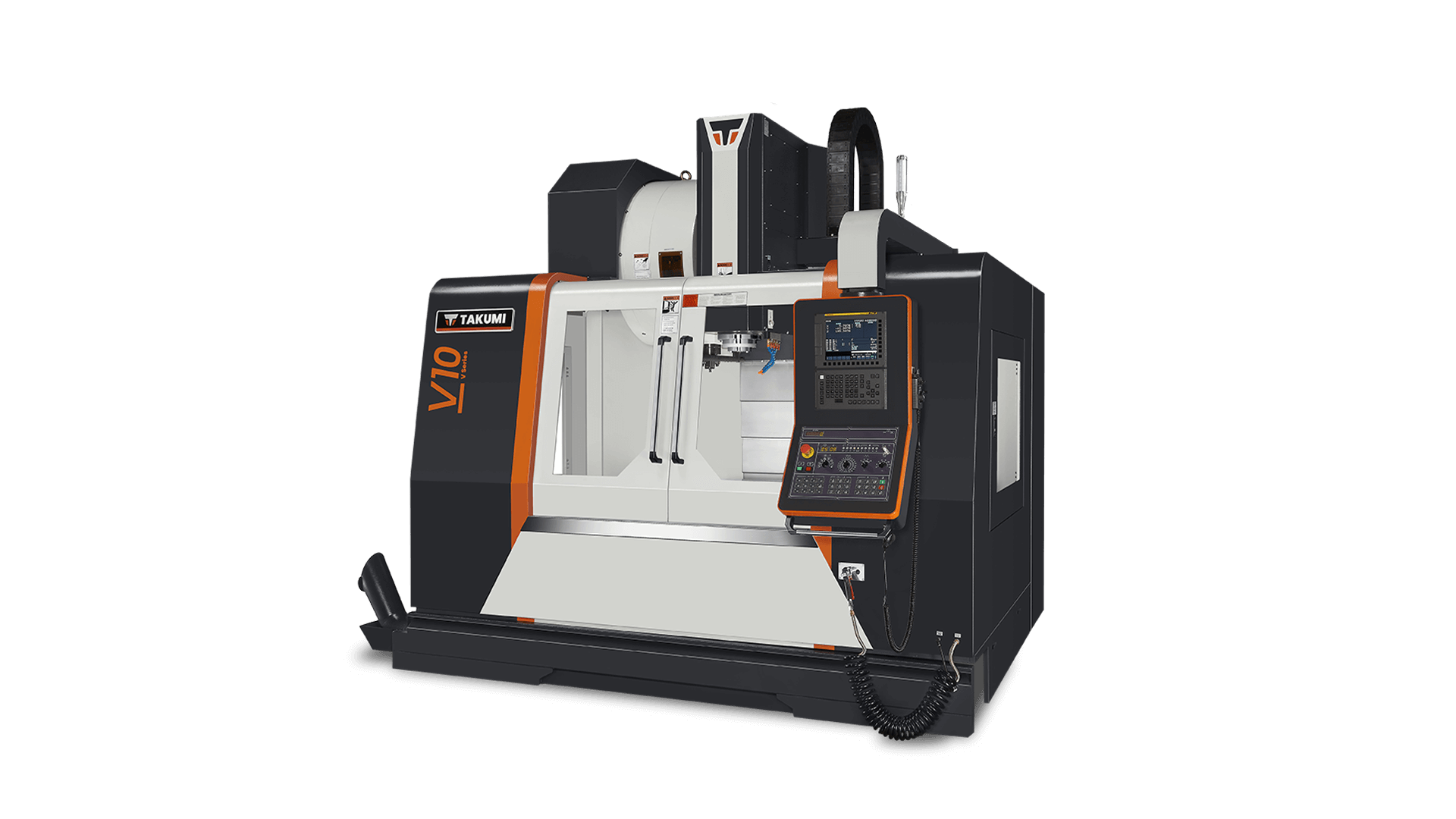

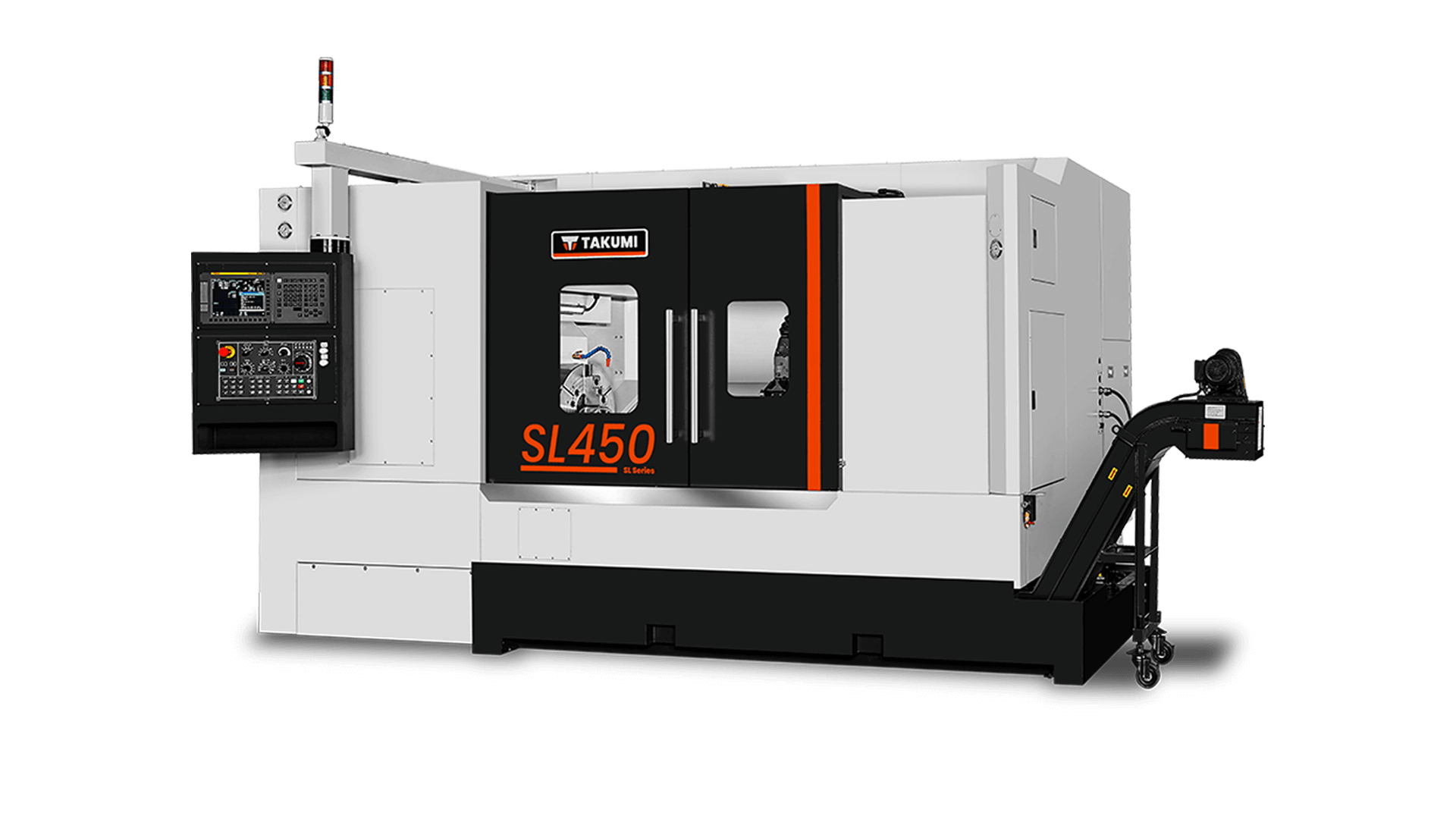

VC1200

3-Axis Vertical Machining Center

VC SERIES CNC Mill

Linear-Guide Mills for Batch or Production Work

Fast Rapids + High Precision

- Rapids of 1417 inches per minute.

- Perfect combination of fast cutting and high stability.

- Pre-tensioned ballscrews minimize thermal growth and improve accuracy.

- Direct-coupled ballscrews increase accuracy.

- Ergonomic table simplifies setup.

- Swiveling control panel optimizes floor space utilization.

- Robust, precision-machined castings.

- Hand-scraped contact areas.

- 30-tool, CAT 40, swing-arm ATC standard.

- Integrated washdown and chip management system.

- Spindle chiller maximizes heat dissipation.

- Absolute encoders ensure fast startup.

- Fanuc© 0i-MF Plus Control.

Technical Specifications

| Travel |

|

|---|---|

| X-Axis | 50 in (1270 mm) |

| Y-Axis | 26 in (660 mm) |

| Z-Axis | 24 in (610 mm) |

| Distance from Spindle Nose to Table | 5.91 ~ 29.92 in (150 ~ 760 mm) |

| Table |

|

| Table Size | 59 x 28.98 in (1500 x 660 mm) |

| Table Max. Load | 2990 lbs (1360 kg) |

| T-Slot | 5 x .71 in on 3.94 in Centers (5 x 18 mm on 100 mm Centers) |

| Spindle |

|

| Spindle Speed | 15000 rpm |

| Motor Power | 14.8 HP (15 KW) |

| Spindle Taper | Big Plus® CAT 40 |

| Feed Rate |

|

| Rapid Traverse (X/Y/Z) | 1417 x 1417 x 994 ipm (36 x 36 x 24 m/min) |

| Cutting Feed Rate | 0.04 ~ 472.44 ipm (1 ~ 12,000 mm/min) |

| ATC |

|

| ATC Type | Swing Arm |

| Magazine Capacity | 30 Tools |

| Max. Tool Diameter | 3.15 / 4.92 in (80 / 125 mm) |

| Max. Tool Length | 11.81 in (300 mm) |

| Max. Tool Weight | 15.4 lbs (7 kg) |

| Tool Shank | CAT 40 |

| Space & System Requirements |

|

| Machine Net Weight | 19842 lbs (9000 kg) |

| Electrical Power Consumption | 35 KVA |

| Pneumatic Pressure | 5 CFM @ 85-115 psi (0.14m3 /min) @ 6-8 bar |

| Operating Dimensions | 207.87 x 139.76 x 122.05 in (5280 X 3550 X 3100 mm) |

Information may change without notice. Optimum machine performance is reliant upon installation conditions at the facility, such as power supply, air supply, and ambient air conditions.