D. Gillette Industrial Services, Inc. in Easton, Pennsylvania explains how Takumi C.N.C. machines help them manufacture high-quality products for the U.S. Department of Defense.

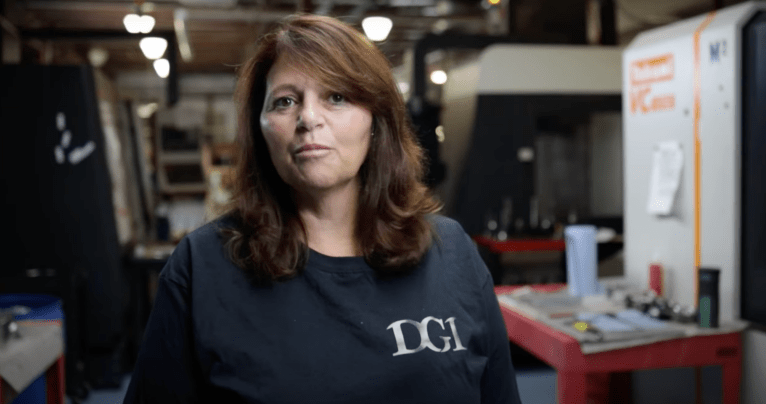

D. Gillette Industrial Services, Inc. (DGI) is a S.B.A. 8(a), third generation Women Business Enterprise located in Easton, Pennsylvania that specializes in the design, fabrication, repair and assembly of parts and equipment. Dee Spencer – who got into manufacturing in the 1980s by working with her grandfather – founded DGI in 2002. The company entered into government contracting in 2015 and has since grown into a leader in Department of Defense (DOD) manufacturing.

“As a business owner and a woman-owned small business, we take great pride in competing in a man’s world.” – Spencer

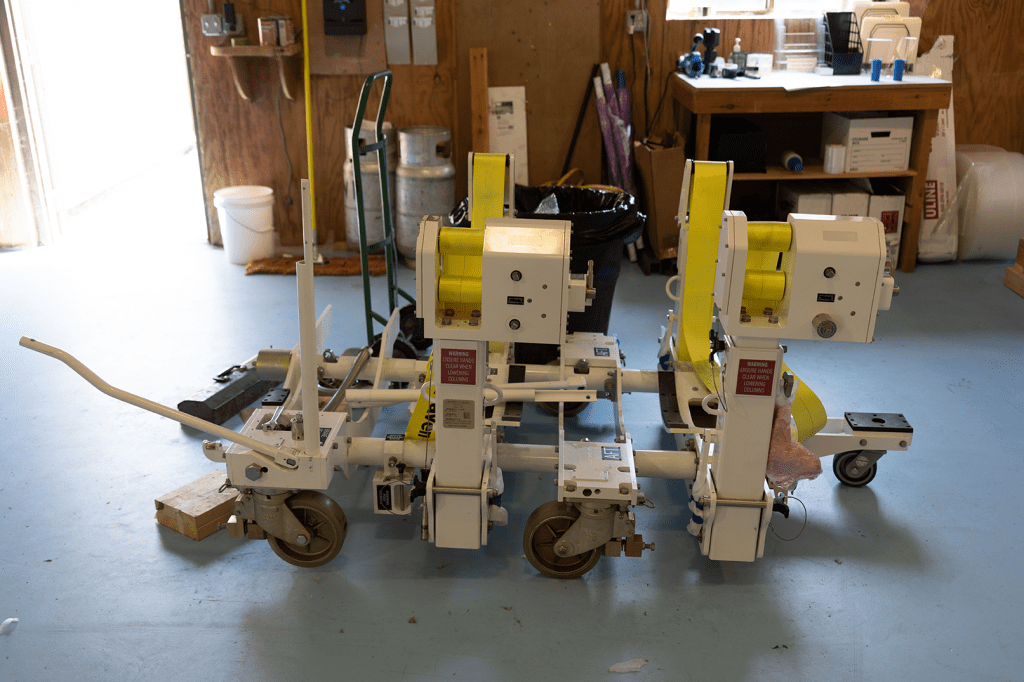

Spencer now leads a team of 16 employees that includes her son, quality engineer Paul Gillette, and lead machinist Richard Bruno. DGI has over 100 contracts with high-profile organizations such as the US Navy, NAVAIR, the US Army, Mars Inc., Mondelez, Kraft Foods and the

National Park Service. Gillette summarizes DGI as a “build-to-print shop.”

“We get blueprints, and we take these blueprints, and we’ll manufacture from the most basic piece to the most complex piece.”

When Spencer first started the company, she used a different manufacturer for CNC (Computer Numerical Control) equipment to cut steel and aluminum but was unhappy with the durability. Gillette added that with the heavy-duty material used in some DOD contracts, DGI would have had to replace their old machines every few months.

“We felt that they were light and almost disposable. We wanted something that was going to go for the long haul,” explained Spencer.

As they searched for an upgrade, the capabilities of the Takumi CNC machines “sold themselves,” said Gillette. DGI ultimately chose Takumi for three main reasons:

● Durability

● Consistency

● Accuracy

DGI now has five Takumi machines, including two VC1052 machines, and is yet to replace one. Spencer is impressed with the consistent results.

“We’ve had no complaints on the quality of our product, and we have the highest amount of inspection on it because the government comes out and inspects them at our facility here. And so if there were a problem it would be caught immediately, and we’ve had 100% acceptance on our products, so we’re really proud of that.” – Spencer

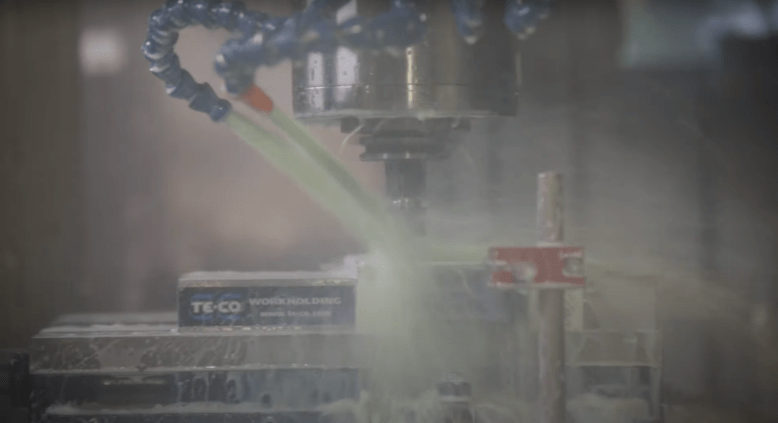

The Takumi V Series CNC machines are equipped with box ways for rigid and stable cutting. Brunco described it as “a beast.”

“It’s amazing to me how it can handle these cuts, and you don’t hear as much as a hesitation of the machine,” he added.

Bruno also noted Takumi’s cooling system, which allows DGI to consistently manufacture high-quality products in blistering conditions.

“The heat in the shop today is going to be ungodly hot, and with the cooling system on these machines, I have never had to make an adjustment in the offsets, which is amazing to me,” said Bruno. “Other brands, the second the temperature goes up you’re constantly making

adjustments. But with these machines I’ve yet to make an adjustment.”

The accuracy of Takumi saves DGI time and effort. Direct-coupled ball screws and motors increase accuracy while providing a faster start-up. The VC Series and V Series C.N.C. machines incorporate pre-tensioned ballscrews to minimize thermal growth, while the H Series machining center uses linear scales for repeatability and accuracy.

“I’ve been in this business for over 30 years,” said Bruno. “The fact that I’ve yet to make an offset adjustment once I have the program set amazes me.”

Bruno considers himself a “classically-trained machinist” and started on manual mills before converting to CNC in the mid-90s. He used Haas CNC machines for about 15 years before making the switch to Takumi. Bruno described the transition as “a learning curve” but said he’ll never go back.

“I love the machines.”

DGI’s latest Takumi machine is the V15. Bruno explained the advantages:

“In the jobs that we do, we were forced to buy a bigger machine to handle a bigger cut. So we got the V15, and to me the horsepower helped tremendously. It allowed me to take deeper cuts, faster cuts, without sacrificing tolerance or not even putting a strain on the machine.”

With the right equipment to meet their needs, DGI manufactures products that are a cut above the competition.

“D. Gillette Industrial Services is set apart from our competitors because of the high quality that we expect from our employees and in our products,” said Spencer. “We have no shortcuts. We deliver on time every time. We have DCMA (Defense Contract Management Agency) inspection on site with 100% quality, and we make our deadlines with on-time delivery.”

Takumi implements stringent processes to design and build rigid and reliable machining centers that exceed customers’ expectations. Gillette offered advice for anyone considering Takumi machines:

“If you’re looking to use Takumi, do your research, reach out to your local reps. They’ve been nothing but outstanding for us, and I’d imagine it’s the right fit for a lot of people.”

Spencer added, “We love our Takumi machines. They help us stay on track, they help us produce our product, and we’re really proud of the warfighter and like to thank them every day.”

For more information, contact:

Dee Spencer

D. Gillette Industrial Services, Inc.

1510 Richmond Rd.

Easton, PA 18040

Phone: 610-438-0889

Email: contact@deegindustries.com

Website: dgindustrialservices.com

Takumi USA

7220 Winton Dr.

Indianapolis, IN 46268

Phone: 1-844-302-3792

Email: info@takumiusa.com

Website: takumiusa.com