Design Features

At Takumi, we implement stringent processes to design and build rigid and reliable machining centers that exceed our customers’ expectations. From our meticulous manufacturing processes, such as hand scraping contact areas, to the use of premium components, we infuse quality into each of our products.

Extra wide door openings facilitate loading and unloading, explosion-proof, large windows provide optimal visibility, and ergonomic tables simplify setup. Swiveling CNC control panel and user-friendly operator interface optimize floor space utilization and allow multiple operation positions.

Rigidity

- The Takumi V Series CNC machining centers are equipped with box ways for rigid and stable cutting.

- The Takumi H Series CNC machining centers utilize roller-type rails on all axes for added rigidity.

Stability

- Robust, precision-machined casting with hand-scraped contact areas.

- All Takumi CNC machines include spindle chillers for maximum heat dissipation.

Accuracy

- Direct-coupled ballscrews and motors increase accuracy while providing faster startup.

- VC Series and V Series CNC machines incorporate pre-tensioned ballscrews to minimize thermal growth, while the H Series machining centers uses linear scales for repeatability and accuracy.

Speed

- All Takumi CNC machining centers include absolute encoders for fast startup.

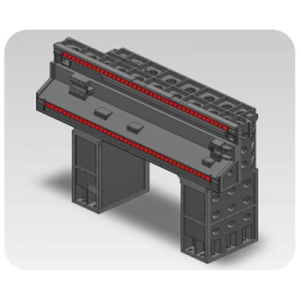

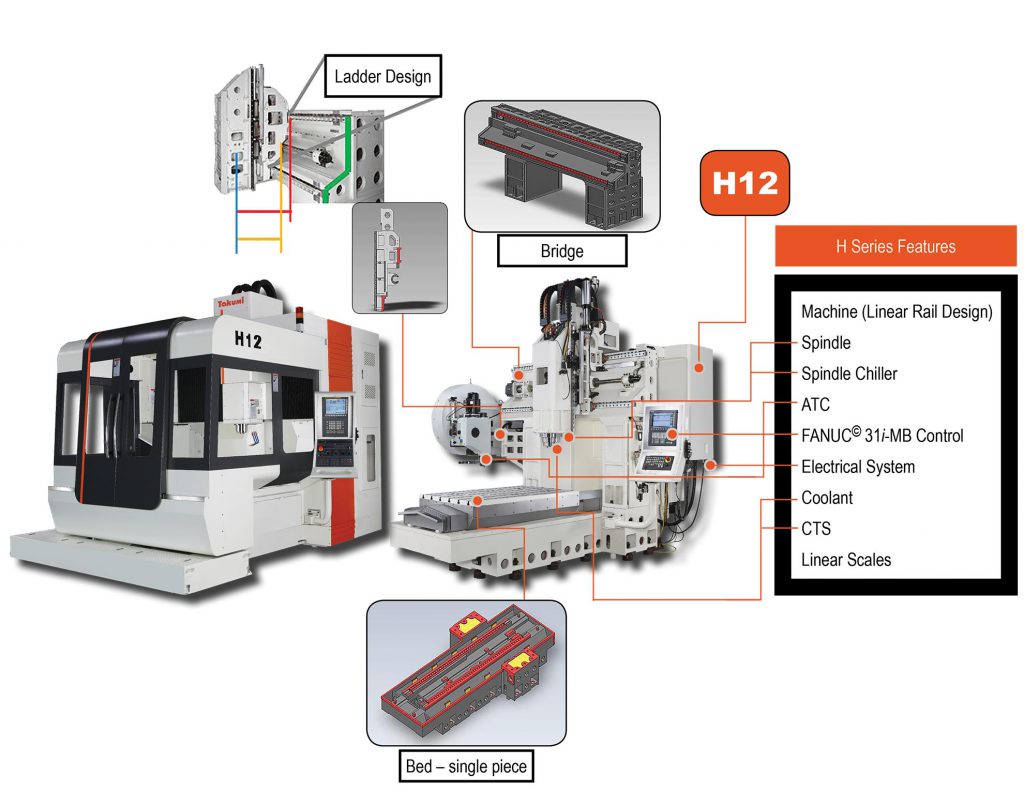

Design Features | H Series | Double Column

- Ladder design of the cross rails provides a rigid support for the saddle and head and prevents deformation in the vertical axis, allowing faster speeds and highly accurate 3D surfacing operation.

- Close proximity of the spindle to the bridge casting reduces overhang.

- Why it matters: implementing a ladder design of the cross rails provides a rigid support for the saddle and head and prevents deformation in the vertical axis. Therefore, it promotes faster speeds and produces highly accurate 3D surfacing operations.

- What’s the alternative: The opposite of a ladder design is the use of light weight castings and flat front or “wall” design cross rails.

- Double-column design, featuring a robust, one-piece construction.

- Low-mass design of the headstock provides excellent thermal stability and increased speed.

- Spindle motor is thermally isolated from the casting, eliminating the main source of heat in the system from transferring to the head.

- Why: Because heat is the enemy; it causes vibration and thermal distortion.

- Single-piece-base design absorbs the thrust force of the table, preventing the column distortion found on typical C-frame machines.

- Roller-type rails on all axes increase rigidity and enable high table loads compared to ball-type guides.

- Linear scales ensure repeatability and accuracy.

- Direct-coupled motors and double-anchored ballscrews eliminate lost motion, as well as the heat buildup found in belt-driven machines.

- Absolute encoders ensure worry-free operation and unrivaled accuracy control at high feedrates.

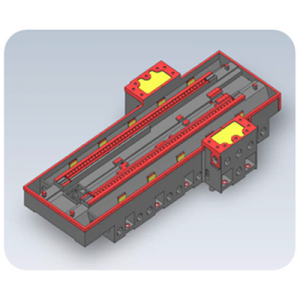

Design Features | V Series | Box Way

- Large box ways for RIGID and HEAVY cutting.

- High-torque, geared-head spindles.

- Large Y-axis travels.

- Chip management includes internal augers to move the chips to the chip conveyors.

- Direct-coupled motors and double-anchored ballscrews eliminate lost motion and heat buildup found in belt-driven machines.

- Absolute encoders ensure worry-free operation and unrivaled control of accuracy at high feedrates.

- Extra wide base increases stability and support of the saddle.

- Wide column support for heavy cutting operations.

- Advanced guided counter-balance design reduces sway and bounce found in other machines.

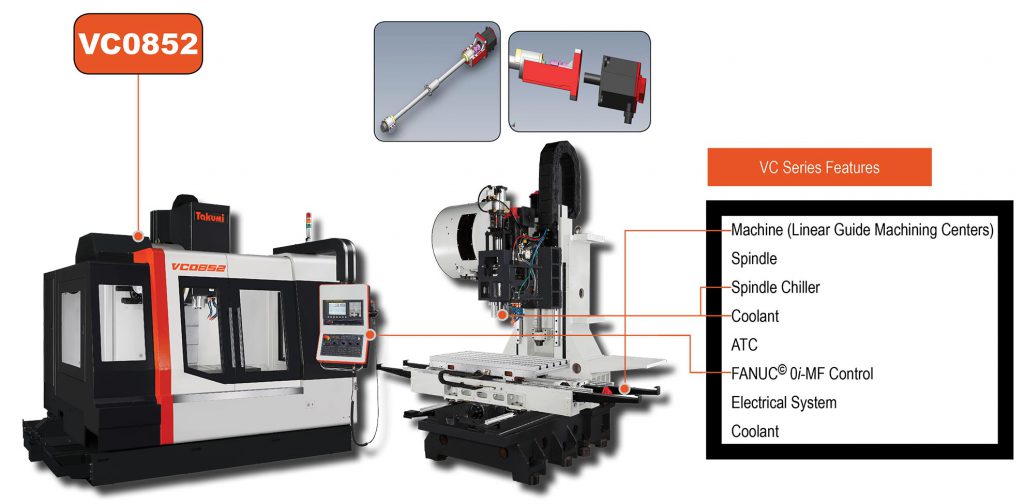

Design Features | VC Series | Linear Guideway

- Direct-coupled motors and double-anchored ballscrews eliminate lost motion, as well as the heat build-up found in belt driven machines.

- Absolute encoders ensure worry-free operation and unrivaled accuracy control at high feedrates.

Design Features | U Series | 5-Axis

- With the U600 and U800, Takumi offers the optimal spindle for your demands.

- Spindle speeds from 15000 to 20000 rpm.

- Output up to 13.41kW – 33.53kW

- Interface: Big Plus® CAT 40 – HSK-63A

- The load-bearing mechanical structures, such as bed, pillar and bed sledge, are made of heat-treated and stress-released Meehanite cast iron. The thereby gained absorption capacity enables a low-vibration machining processes. This ensures high surface quality on the workpiece and increases the tool life.

- Portal construction and stepped column for maximum rigidity, optimized force flow, minimization of the spindle overhang and increased dynamics

- Three-plybed

- Quality components from well-known manufacturers guarantee durability and achieve the desired results:

- Oversized, high-precision, roller linear guides in all three axes.

- Pre-tensioned ballscrews to absorb thermal deformation and maintain maximum accuracy.

- Six or more guide blocks per axis generate a balanced performance between dynamics and accuracy.

- Extremely generous loading accesses: both loading large components by crane and short setup times for smaller components run smoothly based on the interference-free design.

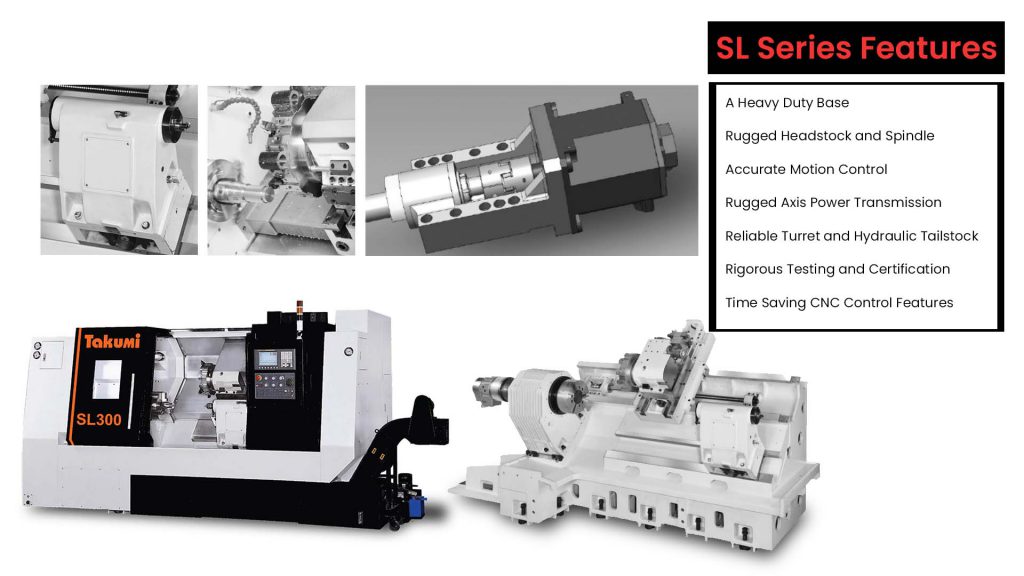

Design Features | SL Series | Lathes

- Heavy-duty base

- Rugged headstock and spindle

- Accurate motion control

- Rugged axis power transmission

- Reliable turret and hydraulic tailstock

- Rigorous testing and certification

- Time-saving CNC control features